Description

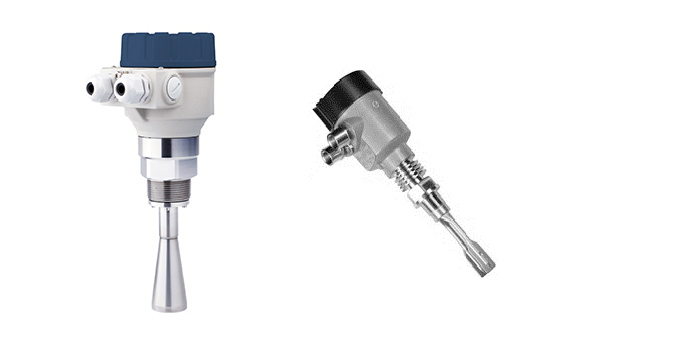

Ultrasonic Level Transmitter

Capacitance type Level Indicator/Transmitter

Radar type Level indicator/Transmitter

Level Switches

Level transmitters are devices used to measure and transmit information about the level of a substance or material in a container, tank, or vessel. They provide continuous or point-level measurements, converting the level of the substance into an electrical signal for monitoring, control, or data acquisition purposes. Here are some key features and types of level transmitters:

1. Measurement Technologies : Level transmitters utilize various technologies to measure the level of a substance. Some common measurement technologies include:

Differential Pressure (DP) Transmitters : These transmitters measure the pressure difference between the bottom of the tank and the liquid surface. They use the hydrostatic pressure principle to determine the level.

Ultrasonic Transmitters : Ultrasonic level transmitters emit ultrasonic waves that bounce off the surface of the material being measured. By measuring the time taken for the waves to return, the distance and thus the level can be calculated.

Guided Wave Radar (GWR) Transmitters : GWR transmitters use guided microwave signals that travel along a probe or cable inserted into the tank. The time taken for the signal to reflect back indicates the level of the material.

Capacitance Transmitters : Capacitance-based level transmitters use the principle of varying capacitance between two electrodes to determine the level. As the material level changes, the capacitance changes, which is then converted into a level reading.

Radar Transmitters : Radar level transmitters emit microwave signals that travel at the speed of light and are reflected back by the surface of the material. The time taken for the signal to return is used to calculate the level.

Hydrostatic Transmitters : Hydrostatic level transmitters measure the pressure exerted by the liquid column above the sensor. This pressure is converted into a level reading.

2. Output Signals : Level transmitters provide various output signals to transmit the level measurement information to control systems or monitoring devices. Common output signals include analog signals such as 4-20 mA or 0-10 VDC, as well as digital communication protocols like HART, Foundation Fieldbus, Profibus, or Modbus.

3. Mounting Options : Level transmitters can be mounted externally or directly inserted into the tank or vessel. External transmitters use non-intrusive methods like ultrasonic or radar to measure the level without physical contact. Insertion transmitters are immersed into the substance being measured and typically use technologies like DP, capacitance, or GWR.

4. Communication and Integration : Many level transmitters support digital communication protocols, allowing for advanced functionality, remote configuration, diagnostics, and seamless integration with control systems or data acquisition systems. This enables real-time monitoring, control, and optimization of the level measurement process.

5. Hazardous Environments : In environments with potentially explosive atmospheres, such as oil refineries or chemical plants, level transmitters may need to be intrinsically safe (IS). Intrinsically safe transmitters are designed to prevent the generation of sparks or excessive heat, ensuring safe operation in hazardous areas.

6. Application-Specific Considerations : Different level transmitters are designed for specific applications and environments. Factors such as the nature of the substance being measured (liquid, solid, slurry, etc.), temperature, pressure, viscosity, and the presence of corrosive or abrasive materials need to be considered when selecting an appropriate level transmitter.

Level transmitters are widely used in industries such as oil and gas, chemical processing, water and wastewater treatment, food and beverage, pharmaceuticals, and many others. They play a crucial role in process control, inventory management, safety, and efficiency by providing accurate and reliable level measurement data.