Description

Pressure Gauges

Differential Pressure Gauges

Pressure Transmitters

Pressure instruments are devices used to measure and monitor the pressure of a fluid (liquid or gas) in a system. They are essential for process control, safety, and performance optimization in various industries, including oil and gas, manufacturing, chemical processing, and HVAC.

Here are some common types of pressure instruments :

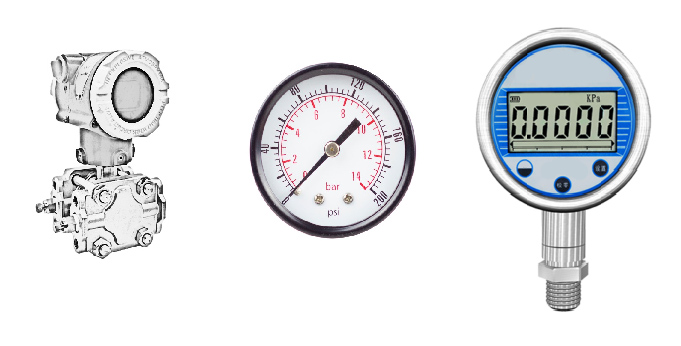

1. Pressure Gauges : Pressure gauges are mechanical devices that display the pressure of a fluid as a reading on a dial. They typically consist of a bourdon tube or diaphragm that deforms under pressure, which is then translated into a dial reading. Pressure gauges come in various configurations, including analog and digital, and can have different pressure ranges and units of measurement.

2. Pressure Transducers/Transmitters : Pressure transducers, also known as pressure transmitters, are electronic devices that convert the pressure of a fluid into an electrical signal. They use sensing elements such as strain gauges, piezoelectric sensors, or capacitive sensors to measure pressure and then provide an output signal (e.g., voltage or current) that corresponds to the pressure value. Pressure transducers can be connected to control systems or data acquisition systems for monitoring and control purposes.

3. Pressure Switches : Pressure switches are devices that sense pressure and provide a binary output (on/off) based on preset pressure thresholds. They are commonly used for safety or control applications, where specific pressure limits need to be monitored. When the pressure exceeds or falls below the set threshold, the pressure switch triggers an electrical signal to activate or deactivate a specific operation or alarm.

4. Manometers : Manometers are simple pressure instruments that use a liquid column to measure pressure. They typically consist of a U-shaped tube partially filled with a liquid (e.g., mercury, water) and measure the pressure difference between two points. The height difference of the liquid column indicates the pressure.

5. Vacuum Gauges : Vacuum gauges are pressure instruments specifically designed to measure pressures below atmospheric pressure. They can be based on different principles, such as Bourdon tubes, capacitance, or thermal conductivity, to measure and display vacuum levels.

6. Pressure Relief Valves : Pressure relief valves are safety devices used to protect equipment and systems from excessive pressure. They automatically open when the pressure exceeds a predetermined set point, allowing the excess pressure to be relieved and preventing potential damage or failure.

7. Pressure Regulators : Pressure regulators are devices used to control and maintain a specific pressure level in a system. They ensure that the pressure downstream of the regulator remains constant, regardless of variations in the upstream pressure or flow rate.

8. Differential Pressure (DP) Instruments : Differential pressure instruments measure the difference in pressure between two points in a system. They can be used to monitor flow rates, filter clogging, or level differences in vessels. Examples include DP transmitters, DP flow meters, and DP level transmitters.